Recognizing Impending Hydraulic System Failures

Catching an impending hydraulic failure before the system actually goes down can often mean the difference between a simple repair and a complete hydraulic overhaul, saving you both time and money.

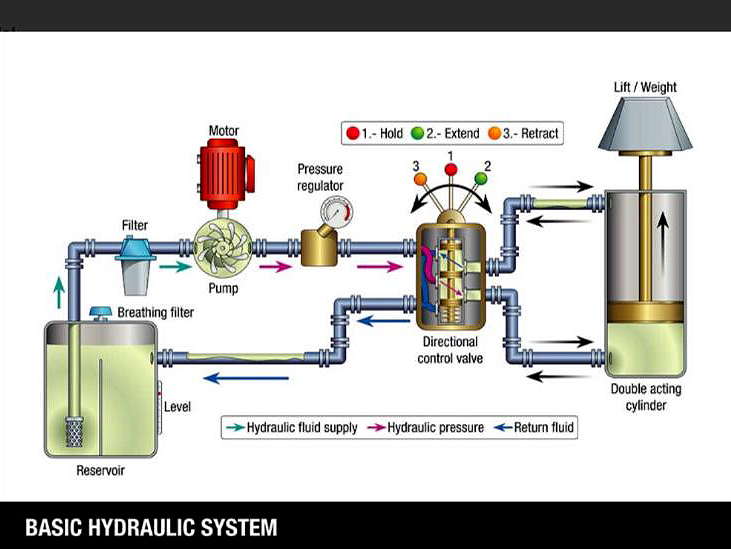

Many of the failures in a hydraulic system will show similar symptoms: a gradual or sudden loss of pressure, resulting in loss of power or speed in the cylinders or motor. In fact, the cylinders may stall under light loads or may not move at all. Often the loss of power is accompanied by an increase in the pump noise, especially as the pump tries to build up pressure.

Any major component (pump, relief valve directional valve or cylinder) may be at fault. In a sophisticated system, other components could be at fault, and this would require the services of a technician experienced in hydraulic repairs.

By following an organized step-by-step testing order, the problem can be to a general area, then, each component in that area can be tested or replaced. All testing of a hydraulics system should be performed with the fluid in the system at normal operating temperature, about 100 degrees F.

This is the most efficient and effective way to troubleshoot hydraulics, and keeping your equipment running at peak performance.